Research

Ongoing projects¶

Elementary plasticity mechanisms in Refractory Concentrated Complex Alloys (RCCA)¶

In 2004, Cantor in England and Yeh in Korea succeeded in mixing 5 elements in equal proportions to create enough entropy to avoid the nucleation of brittle intermetallic phases, leading to an ideal single phase solid solution. Not only did this work perfectly, since these High Entropy Alloys (HEA, or Complex Concentrated Alloys, CCA) often possess properties superior to the best alloys, it also stimulated the discovery of new mixtures among the 10^{78} combinations of metallic elements in the periodic table. An exploratory field combining artificial intelligence models, thermodynamics, elaboration and characterization is helping to identify the most promising compositions. For our part, we're investigating the elementary mechanisms involved in the deformation of these alloys. One of the main questions is the relationship between the movement of dislocations and the local chemical environment in their a priori perfectly disordered core. How will temperature and mechanical stress disrupt the apparent disorder ? What are the role of interstitial solute atoms ? ... are other exciting questions we try to tackle.

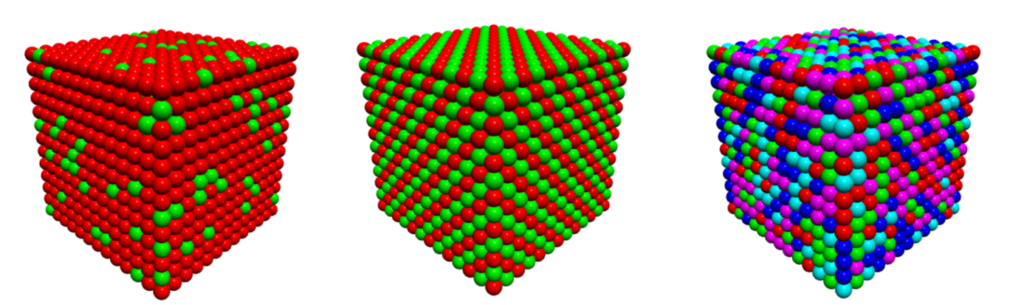

Schematic atomic representation of a conventional alloy (left), an intermetallic alloy (middle) and a High Entropy alloy (right).

This work is supported by 2 ANR projects: DoReMi (Development of New Advanced Refractory Concentrated Complex Alloys with Eutectic Carbide/BCC Microstructures) (ICMPE - LSPM - IRCP - CEMES) (2024-2028), and DisMecHTRA (Dislocation Mechanisms at High Temperature in Refractory complex concentrated Alloys) (CEMES - ICMPE - CEA/SRMP - MatéIS)(2025-2029)

Computer vision for dislocations¶

The study of the dynamics of dislocations in-situ in TEM generates a large quantity of image sequences. For the moment, only human experience allows us to visually isolate the movement of these defects which appear with various contrasts. The manual quantitative analysis that we do from these images is very time consuming and potentially leads to statistical biases by sampling part of the data and averaging the quantities. We are currently working on an approach combining machine learning and computer vision methods to derive characteristic parameters of dislocations (local curvatures, pinning distributions, growth…) during their dynamics. The obtained data should allow a closer dialogue with numerical simulations, in particular at the mesoscopic scale.

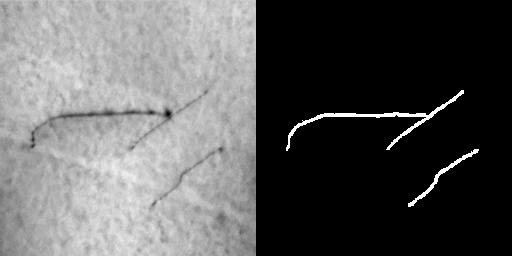

A real dislocation image and its targeted segmentation as predicted by a neural network

This project is supported by the labex NanoX (Distrack)

Elementary plasticity mechanisms for nuclear materials¶

For a better understanding of long term irradiation impact on the mechanical behavior of different structural materials (steels for vessels, fuel cladding), it is crucial to dispose of a solid understanding of elementary mechanisms of plastic deformation. In that purpose, we perform in-situ TEM experiments at high temperature (operating temperature) in irradiated materials under stress, or under electron irradiation and stress in model materials. These experiments are coupled with numerical modeling (Dislocation Dynamics or Object Kinetics Monte Carlo for diffusion processes).

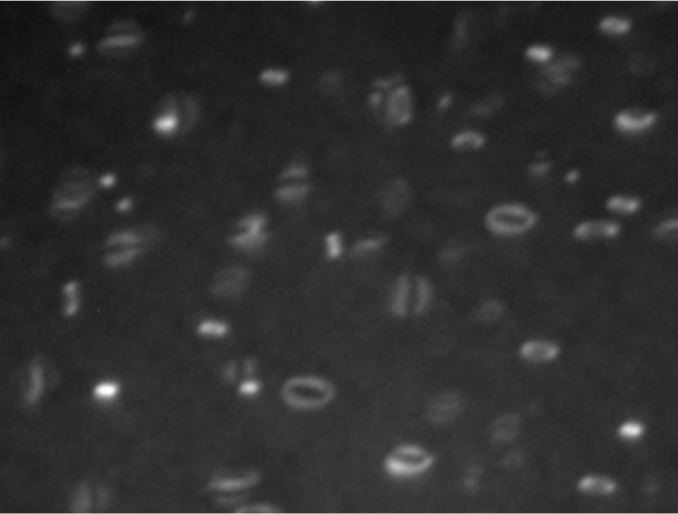

Radiation induced loop microstructure in an in-situ electron irradiated Al sample

This work is supported by a collaboration with CEA Saclay.

Instrumentation for TEM¶

We contribute to the development of dedicated holders for in-situ TEM.

Past projects¶

Small scale plasticity¶

Materials that have at least one of their characteristic length scale reduced (bulk nanostructured materials, nanocrystalline fibers or films) exhibit different mechanical properties than their equivalent counterparts. We study these size effects from both an experimental by performing in-situ Transmission Electron Microscopy (TEM) experiments but also with numerical and analytical approaches. We study especially: coupling between grain boundary migration and plastic strain, dislocation nucleation processes and dislocation/grain boundaries interactions.

Interphases related deformation mechanisms¶

The study of mechanisms related to interface migration between two phases (especially in the martensitic transformation), is an inextinguishable topic of metallurgy, as it has a strong impact on the design of modern alloys (steels, TRIP/TWIP Ti-alloys...). We are performing fundamental studies, thanks to in-situ TEM, on the way interfaces nucleate, migrate and especially how they relax stress during phase transformation, and on how these transformations interact and influence with other deformation mechanisms.